At The Worktable: Flatpack Furniture Assembly Tips

From IKEA to Office Depot and beyond, flatpack furniture is really popular. When it's assembled the right way, it might surprise you how durable and attractive your furniture can be.

They always suggest building on a carpet or using the cardboard from the shipping box. This is to protect the pieces. Other advice says to lay down towels or a blanket instead. I'm here to tell you that if you can get one, beg, buy, borrow, whatever, get a moving blanket instead.

The problem is that most people want to rush. Get it done fast and do the least amount of work necessary. This leads to furniture that gets scraped, scratched, falls apart and breaks easily.

My number one piece of advice is not to rush it. It takes time to properly unpack, sort pieces, and actually assemble in a way that doesn't damage the pieces or the hardware as you go along. DO NOT RUSH! Don't lollygag, especially if your building for someone else. But do everyone a favor and slow down enough to do it right.

Next, don't ignore the directions. There are sometimes pieces in which the only difference between multiples is the placement of a single hole. More than one project has gone off the rails because attention to the directions was not given.

When the directions say to use a hammer, have a tack hammer. 9 times out of 10 it's for tapping in metal or wooden dowel pegs into holes. Use a tack hammer, NOT a 16 ounce hammer or bigger. Those have a tendency to break dowel pegs, especially wooden ones. You'll want a regular hammer to use in other assembly situations like putting "nail on" foot pads onto tables and desks.

Have a pair of stubby screwdrivers handy. One Phillips, one slotted. Often and especially if you have big hands, the spaces on interior points where you have to turn cam locks or put in screws can be unusually small or awkward.

You will NEVER regret having a low torque powered screwdriver. The time it saves and carpal tunnel it prevents will pay for itself. You'll use it mostly on the lowest torque setting but having one or two higher settings will be a big help when putting screws into plastic or other more solid materials. Always keep a good grip though. Sudden stops can twist the power screwdriver right out of your hand.

Having said that, when it comes to turning cam locks and such things, you don't want to overpower them and it's easy to do. You get a much better sense of how much force to use when you use a regular screwdriver for those.

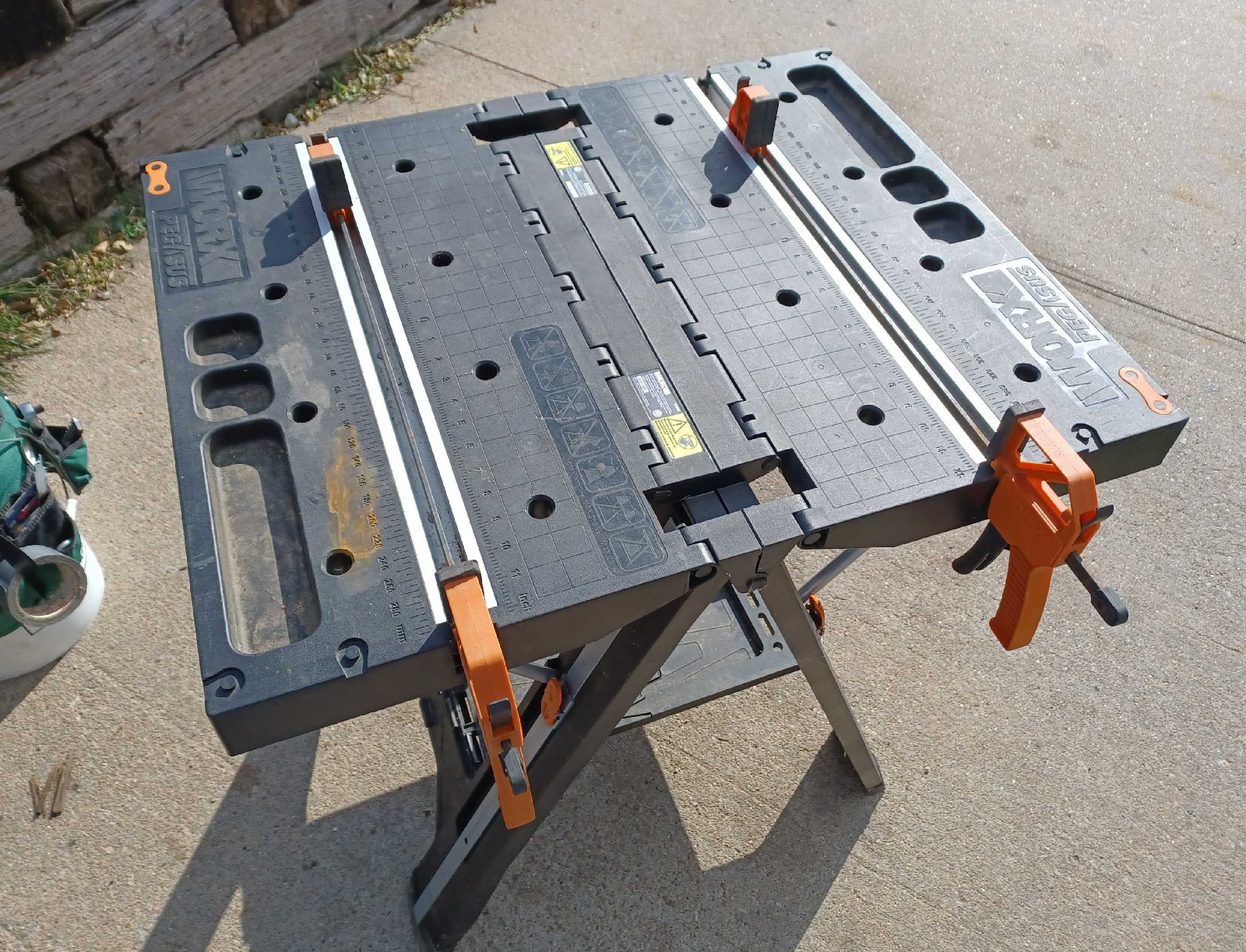

Whenever you can, bring the work up to your level. Get off the floor as much as you can. Assemble on a portable worktable or sawhorses or something if you can. Sit when you can, especially doing smaller pieces like drawers for desks and file cabinets.

They always suggest building on a carpet or using the cardboard from the shipping box. This is to protect the pieces. Other advice says to lay down towels or a blanket instead. I'm here to tell you that if you can get one, beg, buy, borrow, whatever, get a moving blanket instead.

Most towels and regular blankets are too thin and too loosely threaded to prevent much more than simple scratches. Using a moving blanket protects the pieces from scratches, dents, scrapes, dings and other damage that towels and regular blankets won't stop. Moving blankets also protect the floors from damage as well.

Pay very close attention to how you install flatpack hardware into the predrilled holes for them. If you place them in crooked or upside down or something like that. Things like flanged quicklok cam connectors. It's largely plastic and if you aren't careful with placement and inserting it into the corresponding holes, they can break apart. There's no coming back from that. You'll play heck getting it back out and hope that you have an extra somewhere.

Lastly, if you want to make more permanent and stable connections, using a good adhesive on joints and wood dowel pegs is a big help. BUT! Do not use a fast setting adhesive. There are many situations in which you will have to take things back apart and re-fit or adjust, even replace. If you use a fast setting adhesive, you will be in trouble.

That's the guts of it. I can't say it enough, to get the best results, do not rush. The Devil is most certainly in the details where flatpack furniture is concerned. Pay those details the proper respect and you'll have a happy ending. Ignore those details at the risk of utter failure and disappointment.

Comments

Post a Comment