Is particleboard an option for your next project?

Prices on 1/2" thick 4x8 plywood sheets are going for about $53.00 currently. The equivalent size particle board sheet is going for about $24.00 per sheet or roughly half the price.

But I mean, it's particle board, what are you going to build with that? A sub-floor? What does it have going for it?

Well, particle board has some benefits. It's usually lighter than plywood. It's surface is usually smoother than plywood. It's considered to be more environmentally friendly than plywood because it's recycled wood chips glued and compressed together. Basically they're recycled wood sheets. Last but not least, it costs much less than plywood.

Obviously, particle board has some detractors also. It's not as strong as plywood. It's not as durable as plywood. It's not hard to damage particle board. It swells if it gets wet. And oh yeah, if it burns, it's toxic. So much for eco friendly.

So why consider building with it? Good question. It's answered by saying good looking and affordable furniture. Why do you think IKEA is so successful and popular? When particle board furniture is done right, it actually can be pretty darn nice.

As a local handyman, I assemble a LOT of this kind of furniture for businesses and homes. I mean a LOT of it. If you get well made stuff and be nice to it, it can surprise you in how sturdy and good looking it can be.

So what kind of things might we build out of particle board at home? Think of what you can buy from IKEA, Sauder, and similar un-assembled furniture manufacturers and distributors.

I mean, you don't want to build a bed frame out of it. No way. But you can make the dresser, drawers, night stands, tables, desks, counters, and similar pieces right at home for a fraction of the cost of store purchased items.

Now also consider that you don't work with particle board the same way either. You're not making joints the same way as with plywood or lumber.

Cam locks, metal drawer slides, dowel pegs, quicklock flanged cam connectors.... Basically what we call "flatpack" hardware is how you connect one piece of particle board to another.

Some of it is made cheaply and isn't all that great. But like anything else, not all hardware is made alike. You can buy quality made flatpack hardware.

To install most of it, you screw it directly to the board or you install threaded inserts into the wood. Most of the camlocks and cam connectors require whole to be drilled into the wood at or near the edges with a Forstner but or the like.

There are jigs available or that you can make to make aligning and drilling holes consistent and accurate. That's really important.

To be honest, flatpack hardware isn't just usable in particle board. It is useful in any soft wood, even plywood. Also, it's becoming a lot easier to find the hardware locally at home improvement stores and bigger hardware stores. You can order in bulk online if you really get excited.

Something to consider about particle board is as a backing to a more finished surface. I've seen many pieces that have particle board behind metal, vinyl, or laminate surfaces.

Always remember safety though when you work with particle board. You most definitely want to wear eye protection when cutting and even drilling in to it. Wear some gloves too when you don't need to have tactile contact with it. Below that smooth surface, it gets a little rough.

When you cut particle board, use a fine, many tooth blade. Whether it's a circular saw, a jigsaw or anything else. You also want consistent measurements and cuts. The dependence on installed hardware to make joint connections means that everything MUST line up right or it's going to get real ugly, real quick.

Personally, I like to suggest to people new to using saws and drills to start on particle board. Nothing hones exact, steady cutting skills better than the unforgiving medium of particle board. Why do you think the manufacturers use CNC machines to make their cut pieces?

The machines don't make mistakes in cutting. If there's a dimension error in a CNC cut piece, it's usually because whoever input the data messed up.

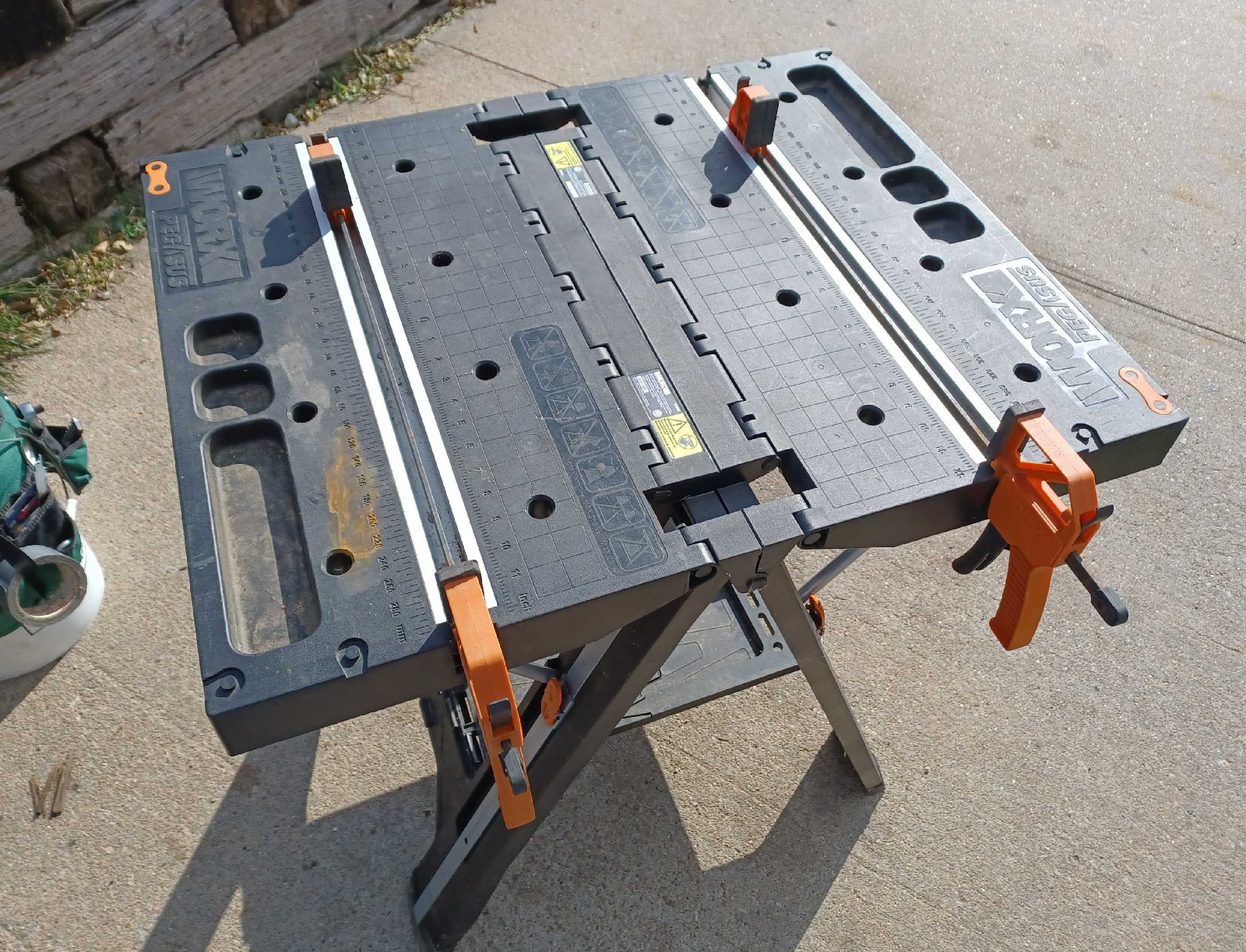

But when we cut and build with particle board in our shops and garages, we don't usually have a spare CNC machine laying around. Just take your time, be careful and remember that the old carpenter's rule is twice as important in this situation. "Measure twice, cut once."

The more accurate you are up front, the less waste you have. Measure it, then measure it again.

With those caveats, particle board projects don't have to be intimidating though. Tool familiarity and more practice are your best friends where particle board is involved.

Personally, I like to make small projects and put laminate over the particle board for a really nice look. A small hanging shelf or curio cabinet build aren't that hard at all and they make great gifts.

Comments

Post a Comment