Phases of Making

As a professional handyman, I do both custom build projects and I do a lot of "pre-fab" install work as well.

There are 4 phases of making or building that I identify and give each it's own emphasis as I work.

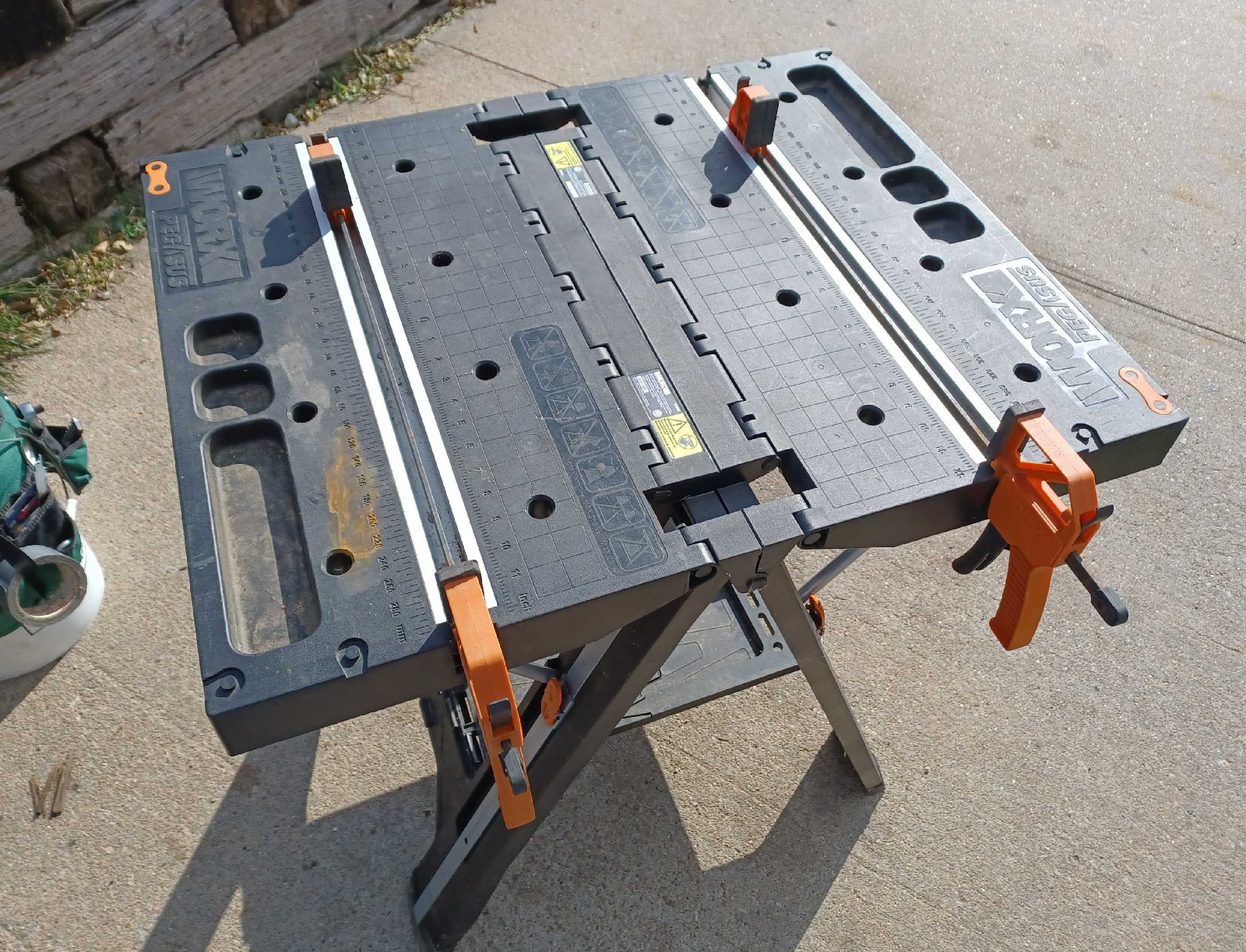

1. Fabrication. This the making or production of the parts of what the project or item is. It doesn't matter what the project is or the role you play, at some point, the item or project was fabricated by you or someone else. The more you can know about fabrication of it, the better prepared you are along through the rest of the phases.

2. Assembly. Once the parts have been made, it's time to put it together. That's assembly. Whether the parts were "pre-fab" or made by someone else or you made them yourself, the next step is to assemble them.

3. Installation. Either after the item or project has been completely assembled or you combine putting certain parts in place (installation) as you go along, the next step is usually installation if it's not a stand-alone item. Installation involves mounting, fastening, embedding, or otherwise putting things into the position and place they are intended to be. As mentioned a moment ago, sometimes items are installed and assembled as you go along.

4. Configuration. Lastly, once it's been made, assembled and installed there is often a need to configure it specifically to meet certain requirements or specifications for the end user. It might be as simple as making basic adjustments or as complicated as entering customized information or adding sophisticated connections.

Being a handyman, probably 75 percent of the work I do is focused on the assembly, installation, and configuration of pre-fabricated items. Ranging from furniture to smart devices to structural accidents locks, doorknobs, windows, etc... I put it together, install it, and usually do some kind of configuration.

By focusing on what happens in each phase of operation, you can be better prepared to do the other phases correctly.

Comments

Post a Comment