Are Corded Tools Still Worth Having?

Occasionally, social media gets even dimber than usual. For example, over the past couple of months there have been a few posts and videos trying to convince people that given the current state of cordless, battery powered tools, corded tools are no longer relevant.

Not only is this wrong, its aggressively stupid. It assumes too much on behalf of the work and people doing it.

Even the best battery powered tools still aren't good enough for multiple, replicated work. If you need a few pieces done, cordless tools are awesome. But if you're making thing in job lots, you'll just burn your batteries up. Corded tools are significantly better for making lots of pieces and parts.

Corded tools are still the best option overall,in my opinion, if you're working in a shop or production environment. Yes, corded tools can sometimes feel clumsy and in the way, but a decently planned and laid out shop can overcome most of that.

The consistent power levels and uninterrupted power source in a shop setting to make multiple, repeated parts and pieces is by far the best situation you'll ask for.

Even out on the job site, some tools get used for specific tasks that are highly repetitive. A jobsite tablesaw or mitresaw for example. When you're only using those tools for quality and consistency of cuts as needed, a battery powered version works fine.

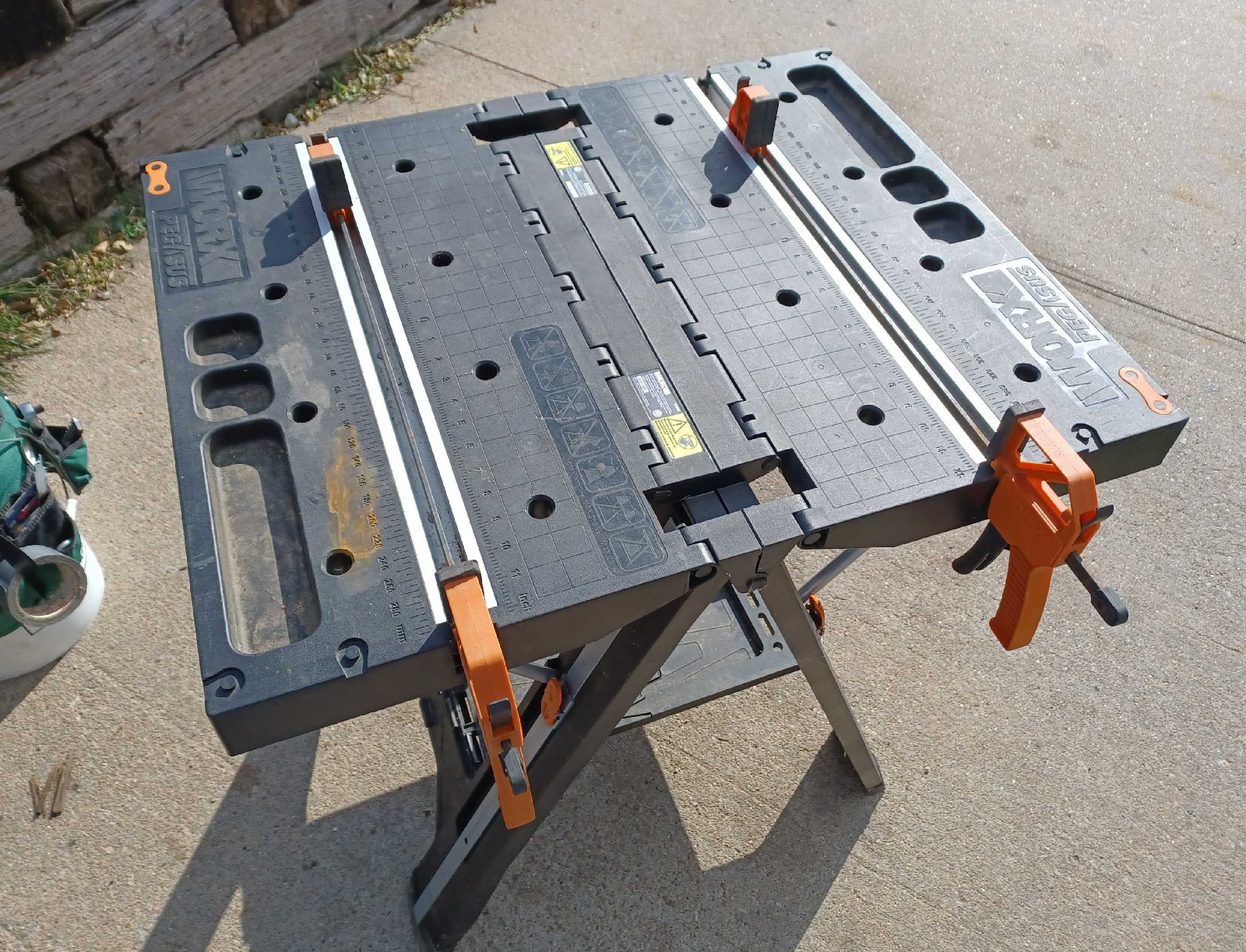

But again, if you're using it to make consistent and repetitive multiples, the corded one is still you're better option. Especially if you can make it a designated workstation on the job site.

As always, there is room for combining both. Certain tools can always seem better in either a shop or jobsite location. It's not really about trying to eliminate a type of tool, but finding which in certain conditions which increase quality productivity.

Comments

Post a Comment